Lag bolts are sturdy fasteners designed for heavy-duty applications. They feature a large diameter and coarse threads. A lag bolt size chart provides essential details on diameter, length, thread pitch, and head styles, ensuring proper selection for wood-to-wood and metal-to-wood fastening projects.

1.1 What Are Lag Bolts?

Lag bolts, often referred to as lag screws, are large, heavy-duty fasteners designed for securing heavy loads. They feature a coarse thread pattern and a hexagonal head. Unlike standard bolts, lag bolts are designed to thread into wood or metal, making them ideal for wood-to-wood and metal-to-wood applications. They are commonly used in construction, decking, and furniture assembly. The bolt’s large diameter and deep threads provide superior holding power. A lag bolt size chart typically includes specifications such as diameter, length, and thread pitch, helping users select the right size for their project. They often require a pilot hole to ensure proper installation and prevent splitting of the material. Lag bolts are known for their strength and durability, making them a reliable choice for structural applications.

1.2 Applications of Lag Bolts

Lag bolts are versatile fasteners used in various applications where strong, durable connections are required. They are ideal for wood-to-wood and metal-to-wood fastening, making them a popular choice in construction, decking, and furniture assembly. Their coarse threads and large diameter provide excellent holding power in both softwood and hardwood. Lag bolts are also commonly used in fencing, landscaping, and heavy machinery assembly. A lag bolt size chart helps identify the appropriate size for specific applications, ensuring optimal performance. Their strength and reliability make them a preferred choice for projects requiring superior load-bearing capacity. Whether for structural support or decorative purposes, lag bolts deliver dependable results.

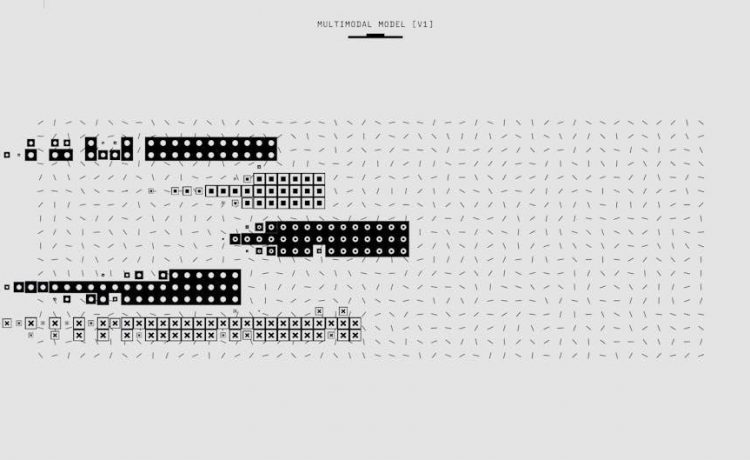

A lag bolt size chart details dimensions, including diameter, length, thread pitch, and head style. It helps users select the right bolt for their project requirements efficiently.

2.1 Diameter and Length Options

Lag bolts are available in various diameters and lengths to suit different applications. Common diameters range from 1/4 inch to 1 1/2 inches, with lengths starting at 1 inch and extending up to 12 inches or more. The size chart provides a clear reference for selecting the appropriate diameter and length based on the specific requirements of the project. For instance, a 1/2-inch diameter lag bolt is suitable for medium-duty applications, while a 1-inch diameter bolt offers greater strength for heavy-duty uses. Proper pairing of diameter and length ensures optimal performance and durability in both wood and metal fastening scenarios.

2.2 Thread Pitch and Type

The thread pitch and type are critical specifications in a lag bolt size chart. Thread pitch refers to the distance between threads, typically ranging from 8 threads per inch (coarse) to 10 threads per inch (fine). Coarse threads are ideal for softer materials like wood, while finer threads suit harder materials. The chart also details thread types, such as standard or coarse, ensuring compatibility with various fastening needs. Proper thread selection enhances holding power and prevents material splitting. Referencing the chart helps in choosing the correct thread pitch and type for optimal performance in different applications.

2.3 Head Styles and Drive Types

A lag bolt size chart includes various head styles and drive types, each suited for specific applications. Common head styles are hex, square, and round washer, offering different aesthetic and functional benefits. Drive types like hex key and Phillips ensure easy tightening and torque application. The chart specifies these options, helping users match bolts to their tools and project requirements. Proper head and drive selection enhances installation efficiency and ensures a secure hold, making the chart an essential tool for precise fastening solutions.

Understanding Lag Bolt Dimensions

Lag bolts’ dimensions include shank diameter, thread length, and overall length. The chart specifies these measurements, ensuring proper fitment. Shank diameter and thread length are critical for load-bearing capacity.

3.1 Shank Diameter and Thread Length

The shank diameter of lag bolts varies, with sizes ranging from 1/4 inch to 1 1/2 inches; The thread length is a critical dimension, typically specified as a minimum requirement. For instance, a 1/2 inch lag bolt has a thread length of about 1 1/2 inches, while larger bolts may have up to 3 inches of threading. These measurements ensure proper engagement in materials like wood or metal. The shank diameter directly affects the bolt’s load capacity, with larger diameters offering greater strength. Understanding these dimensions is essential for selecting the right bolt size.

3.2 Pilot Hole Requirements

Pilot holes are crucial for lag bolt installation. The hole size depends on the material and bolt diameter. For softwood, the pilot hole should be 40-70% of the shank diameter, while hardwood requires 65-85%. Proper sizing ensures the bolt threads engage effectively without splitting the material. Using a drill bit slightly smaller than the bolt’s shank prevents over-drilling, maintaining structural integrity. Incorrect pilot hole sizes can lead to reduced holding power or material damage, emphasizing the importance of precise measurements. Always refer to the lag bolt size chart for specific recommendations based on material type and bolt dimensions to achieve optimal fastening results.

3.3 Material Thickness Guidelines

Material thickness plays a crucial role in selecting the appropriate lag bolt size. For wood, the specific gravity (G) influences the required thread engagement. Softwoods with G ≤ 0.5 need a thread engagement of 40-70% of the shank diameter, while hardwoods with G ≥ 0.6 require 65-85%. In metal-to-wood applications, the metal thickness must be considered to ensure the bolt’s shank fully engages without causing material deformation. The lag bolt size chart provides specific guidelines to match material thickness with bolt diameter and thread length, ensuring optimal holding power and preventing over-tightening or splitting. Proper alignment with material thickness ensures structural integrity and safety in fastening applications.

How to Read a Lag Bolt Size Chart

Lag Bolt Size Chart Overview

A lag bolt size chart outlines diameter and length options, thread pitch, and head styles. It helps users select the right bolt for their application needs.

4.1 Key Measurements and Specifications

When analyzing a lag bolt size chart, focus on diameter, length, and thread pitch. Diameter ranges from 1/4″ to 1-1/2″, with lengths varying from 1″ to 36″. Thread pitch is typically coarse for wood. Pilot hole sizes are 40-70% of the shank diameter for softwood and 65-85% for hardwood. Material thickness guidelines ensure proper fastening without over-tightening. Coating thickness varies by size, with 0.0017″ for bolts under 3/8″ and 0.0020″ for larger sizes. These specifications ensure compatibility and strength in wood-to-wood or metal-to-wood applications, making the chart a vital tool for selecting the right lag bolt.

4.2 Interpreting Thread and Shank Dimensions

Interpreting thread and shank dimensions on a lag bolt size chart is crucial for proper fastening. The shank diameter determines the pilot hole size, typically 40-70% for softwood and 65-85% for hardwood. Thread length and pitch vary by bolt size, with coarse threads enhancing grip in wood. Shank length must match material thickness to avoid over-tightening. Coating thickness, like 0.0017″ for bolts under 3/8″, ensures durability. By aligning these measurements with your project’s needs, you ensure secure and lasting fastening in wood-to-wood or metal-to-wood applications, making the chart an essential reference for accurate bolt selection.

Choosing the Right Lag Bolt Size

Selecting the right lag bolt size involves assessing load-bearing requirements and material thickness. Match bolt diameter and thread length to the project’s demands for optimal stability and durability. Always consult a lag bolt size chart for precise measurements.

5.1 Considering Load and Weight Requirements

When selecting lag bolts, it’s crucial to evaluate the load and weight requirements of the application. Load-bearing capacity is determined by the bolt’s diameter and thread length. A larger diameter and longer thread typically offer greater strength. For heavy-duty applications, such as construction or machinery, choosing bolts with higher shear strength is essential. Always refer to a lag bolt size chart to ensure the chosen bolt can handle the specified load without failure. Proper selection prevents structural issues and ensures long-term reliability in both wood-to-wood and metal-to-wood fastening scenarios.

5.2 Matching Bolt Size to Material Thickness

Properly matching the lag bolt size to the thickness of the material is critical for ensuring a secure and lasting connection. The diameter and thread length of the bolt must align with the material’s thickness to achieve optimal holding power. For example, thicker materials require larger diameters and longer threads to prevent pull-out. A lag bolt size chart provides guidance on selecting the right bolt for specific material thicknesses. Additionally, the pilot hole diameter should be appropriately sized to avoid splitting the material. Always consider the type of material (e.g., softwood, hardwood, or metal) and its density when choosing the bolt size for a strong and durable fastening solution.

Common Applications and Use Cases

Lag bolts are ideal for construction and heavy-duty projects, securing heavy structures and machinery. They excel in outdoor applications like decking and fencing, ensuring durability and strength.

6.1 Wood-to-Wood Fastening

Lag bolts are widely used in wood-to-wood fastening for their strength and reliability. They are ideal for securing heavy wooden beams, decks, and fences. The coarse threads ensure a tight grip, while the large diameter provides excellent load-bearing capacity. Proper pilot hole sizing, typically ranging from 40% to 85% of the shank diameter depending on wood density, is crucial for optimal performance. This ensures minimal splitting and maximum holding power. Lag bolts are particularly effective in outdoor applications where durability and resistance to environmental stressors are essential. Their versatility makes them a preferred choice for both residential and industrial wood construction projects.

6.2 Metal-to-Wood Fastening

Lag bolts are commonly used for metal-to-wood fastening in applications like attaching metal beams or brackets to wooden structures. Their coarse threads and large diameter provide a secure hold in wood. Proper installation involves drilling pilot holes to prevent splitting. The bolt’s head and washer ensure a flush finish. Lag bolts are ideal for outdoor and industrial settings. They are durable and resistant to environmental stressors. Their versatility makes them a preferred choice for construction projects requiring strong metal-to-wood connections; Always refer to a lag bolt size chart to ensure the correct diameter and length for your specific application. This ensures optimal performance and safety in metal-to-wood fastening scenarios.